Products

Paras specializes in manufacturing of high performance injection molded engineering plastic components which are used for various industries such as Agro Pumps, Indian Railways (IR), Telecom and other Industrial applications. The Company's principal product lines consist of market and customer-specific engineered plastic components.

We mold various industrial components from engineering compounds such as modified polyphenylene oxides (mPPO) - NORYL, modified polyphenylene sulphides (mPPS) - NORYL, polyesters such as polycarbonates (PC) and polybutylene terephthalate (PBT), Acrylonitrile Butadiene Styrene (ABS), Polyacetals (POM), Polyamides 6 (PA6), Polyamide 66 (PA66), Flame retardant grades, polypropylene etc with various glass fibre content up to 30% along with flame retardants and manufacturing engineering components with accuracy in microns range.

For Agro pump parts, we supply quality components for submersible pump industry made of our engineering compounds such as modified polyphenylene oxides (mPPO), polycarbonates (PC) with various glass filler contents.

High dimensional precision is achieved with post molding machining of components to adhere to stringent product concentricity norms and requirements.

From MD's Desk

Over the years Paras Plastics has dedicated itself to improving the quality of engineering plastic components by developing innovative and eco-friendly technologies. Customer Satisfaction drives all our actions and we strive to establish Paras as a brand synonymous with trust.

Paras Plastics started in the year 1988 and has gained the trust of its valuable customers with innovative range of products and dedication towards quality. Over the past few years we have introduced many new processes leading to superior product quality and reliability.

Our commitment to customer satisfaction and quality has helped us achieve the position of one of the leading quality suppliers in India.

On behalf of all at Paras Plastics, I extend warm welcome to you and your team and hope you benefit from our extensive product range. Kindly specify the products that interest you and we shall provide you with a technically and commercially viable offer.

Should you require my personal attention, please feel free to contact me at paras@parasplastics.com

Infrastructure

We at Paras work right from the idea phase to design and development and from tooling to manufacturing and supply phase. We strongly believe in working with our customers as project partners and hence our company motto 'Providing Solutions to Engineering Plastics.

We are fully equipped with modern resources and high human skills coupled with years of hands-on experience to fulfil the above. Customer specific application development has always been our strength at the core.

We are equipped with preparing drawings with 2D and 3D models from samples provided along with complete tool design with total engineering. Our experience of over 2 decades in tool designing enable us to design efficient and effective product design.

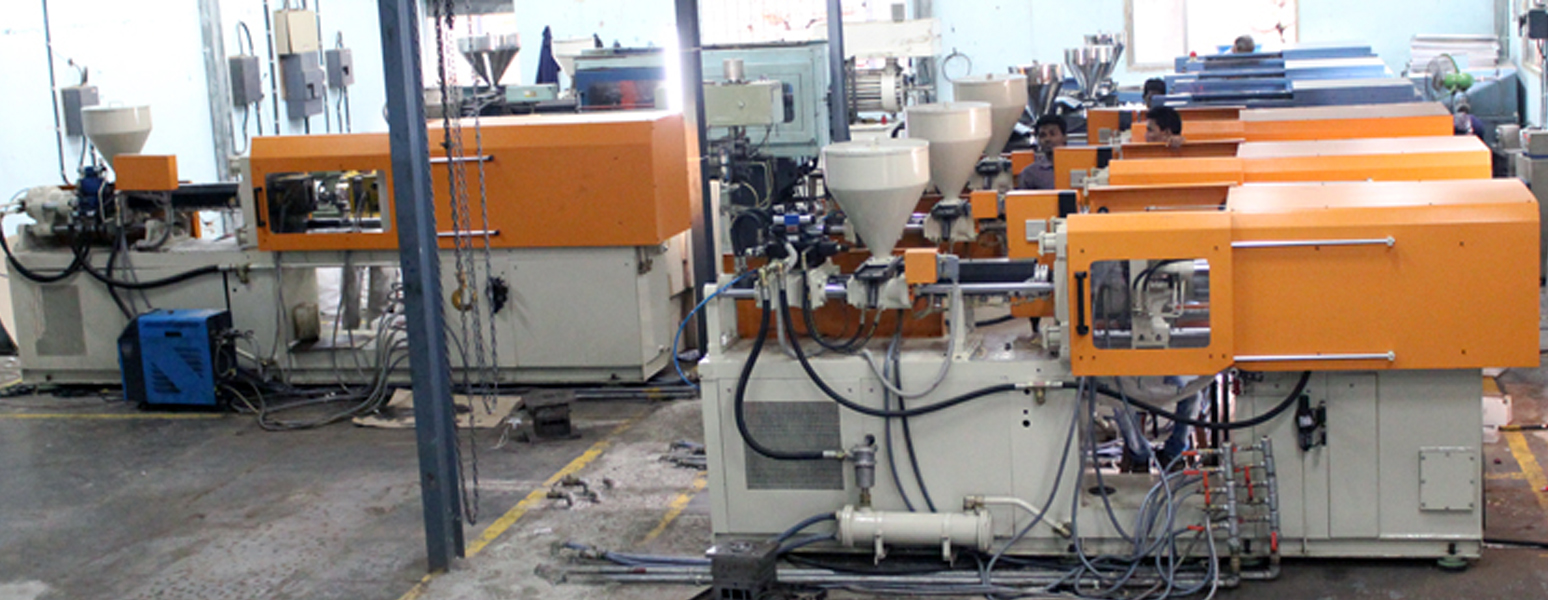

For manufacturing, we are equipped with automatic injection molding machines, ultrasonic welding machines, press fitting machines for molding and assembling of plastic components.

Company's manufacturing facility is also equipped with research and development centre and has its own product testing and quality control laboratories to ensure timely delivery of high-quality products.

Providing superior service and products is Paras' focus for all its injection molded components.

Headquartered in Mumbai, Paras employs 200 people and has 2 manufacturing facilities in Vasai (Mumbai) & Billimora (Gujarat).